|

|

Post by kioskfan on Oct 21, 2017 19:50:04 GMT

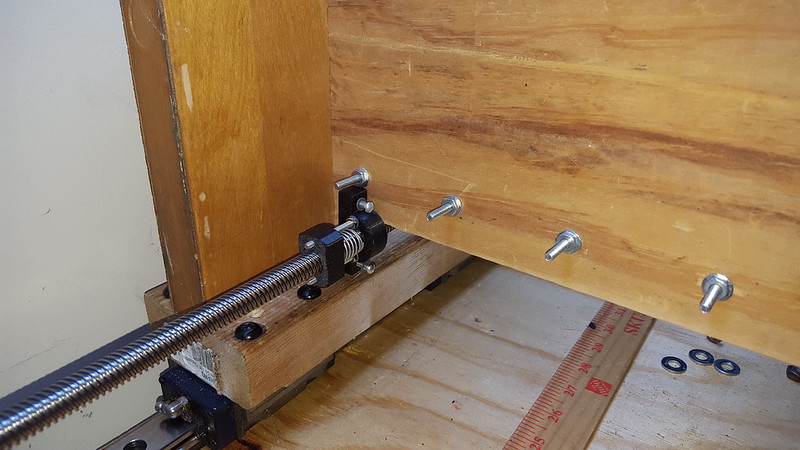

I know it's beautiful isn't it? I've been using and researching acme screws for about ten years and at one point had access to a fancy acme tap which has since gone missing and that's a shame as it cost a few hundred dollars. This tap would have allowed me to create the same style anti-backlash nut as shown above but in a more solid material like brass or steel. Thanks to some kind thingiverse user I found a cad model for this exact thread and I used it to 3D print a few hex nuts just to see if it worked. When I printed and then threaded the nut it was a bit more than surprising that I could actually print a thread, mind you a 1/2" acme thread is about as course as you'll ever see this side of ship or bridge parts.  In the cad image above you can see clearly how the threads on a five start acme nut work. The springs apply tension to keep the nut from wobbling on the threads so the small nut is located from turning by the 10-24 bolts. Better hardware would be some kind of shoulder bolts and I will keep my eyes open for them but for now the tiny threads pose no problem for the amount of travel required here.  The test fixture pictured above allows some torque to be applied and the deviation measured by a dial gauge (not pictured, sorry) Meccano is handy for quick fixtures.  Here's the nut mounted to the side of my Y axis gantry.  Another shot of the gantry. If you'd like to see the CAD files check out my Thingiverse page. |

|

ralf

Junior Member

Posts: 93

|

Post by ralf on Oct 21, 2017 20:05:43 GMT

Really nice! What are you moving with that?

|

|

|

|

Post by tanephar on Oct 21, 2017 20:52:14 GMT

Wow, that is really nice work, and a great instance of lead screw starts.

|

|

|

|

Post by kioskfan on Oct 22, 2017 1:28:35 GMT

Really nice! What are you moving with that?  |

|

ralf

Junior Member

Posts: 93

|

Post by ralf on Oct 23, 2017 15:27:38 GMT

That’s awesome, are you going to replace the wood with aluminium later?

|

|

|

|

Post by kioskfan on Oct 23, 2017 16:54:11 GMT

That’s awesome, are you going to replace the wood with aluminium later? This is the bench top proof version that will allow me to build my controller/power supplies. Most of these parts will be migrated to a larger all steel and aluminum 1 meter by 1 meter production machine. The Z axis is a commercial stage that I happen to have in my parts box, it will be replaced with a larger version able to handle a large spindle. |

|